The mining industry is constantly evolving, embracing new technologies to improve efficiency and reduce costs. Among these innovations, integrating IoT (Internet of Things) and Big Data into NewSteel’s truck boxes significantly optimizes mining operations.

What is IoT and Big Data?

IoT (Internet of Things): IoT refers to a network of physical devices connected to the Internet, collecting and sharing data. These devices include sensors, machinery, and equipment used in mining operations. By connecting these devices, companies can monitor and manage their assets in real-time, leading to improved efficiency and reduced downtime.

Big Data: Big Data involves analyzing large sets of data to uncover patterns, trends, and insights. In mining, Big Data analytics can predict equipment failures, optimize maintenance schedules, and improve overall operational efficiency. By leveraging data from IoT devices, mining companies can make informed decisions, enhancing productivity and reducing costs.

IoT and Big Data in NewSteel Truck Boxes

NewSteel’s truck boxes are equipped with sensors that collect data on various operational parameters, such as load weight, wear and tear, and environmental conditions. This data is transmitted to a centralized system where it is analyzed using Big Data tools to identify patterns and opportunities for improvement.

Benefits of IoT and Big Data Integration

- Predictive Maintenance: IoT sensors in NewSteel truck boxes can predict when maintenance is needed, preventing unexpected breakdowns and reducing downtime.

- Load Optimization: Real-time data on load weights helps optimize loading operations, preventing overloading and underloading, which enhances fuel efficiency.

- Enhanced Safety: IoT sensors monitor environmental conditions and equipment status, alerting operators to potential hazards and improving safety.

Real-World Applications

Mining operations worldwide have seen significant improvements by integrating IoT and Big Data into their processes. For example, a South American mine reported a 15% reduction in operational costs due to predictive maintenance and load optimization enabled by NewSteel’s smart truck boxes.

Continuous Innovation

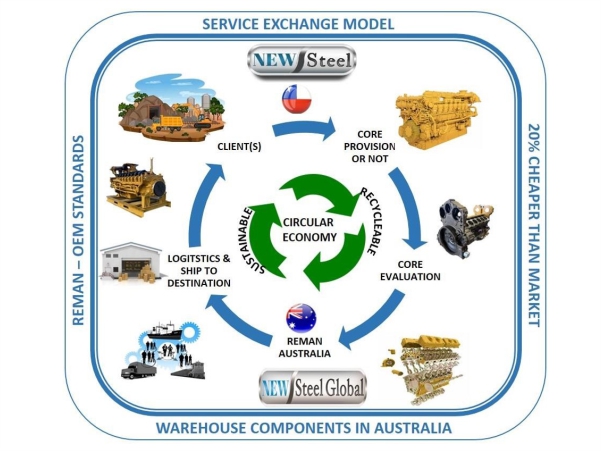

NewSteel continues to innovate, offering advanced solutions that meet the evolving needs of the mining industry. The advanced maintenance and innovative design of their truck boxes exemplify how the company leads in adopting emerging technologies.

Integrating IoT and Big Data into NewSteel’s truck boxes transforms mining operations by enhancing efficiency, safety, and reducing costs. Stay informed about our latest innovations by visiting our article on smart loading and effective work and following us on Instagram, LinkedIn, or contacting us via WhatsApp.