Why Consider Electric Truck Conversion for Your Mining Fleet?

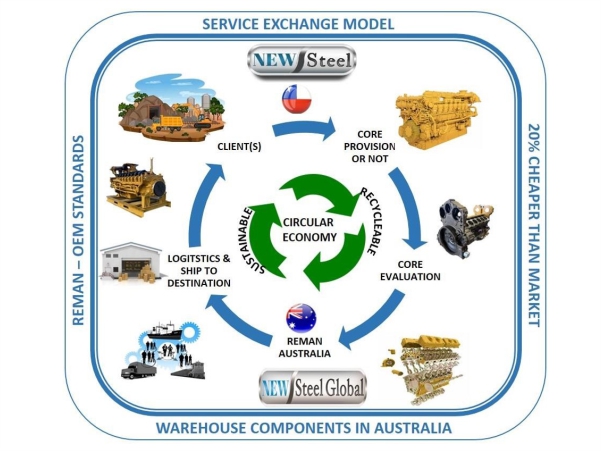

Decarbonization in mining isn’t just a long-term goal achieved by purchasing new electric trucks. With NewSteel, you can start today by converting your existing fleet to electric. This process not only reduces carbon emissions but also significantly enhances efficiency and sustainability, offering a practical solution for modernizing mining fleets.

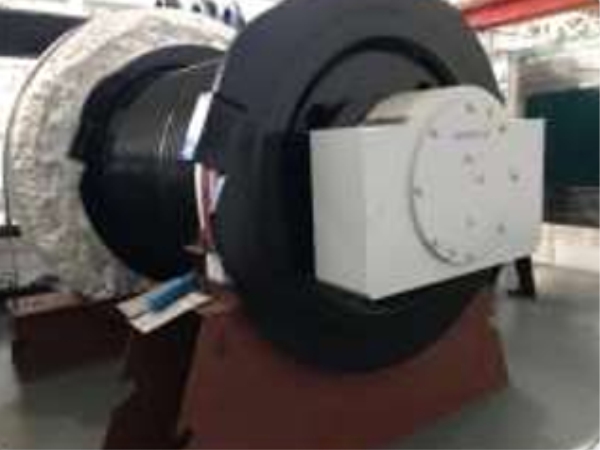

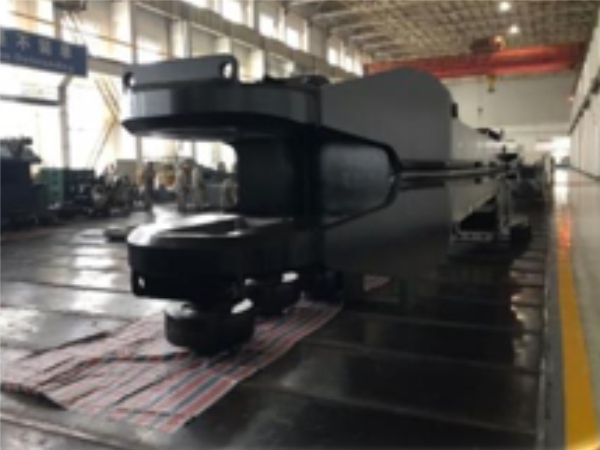

Core Components of the Conversion Process

NewSteel’s electric truck conversion involves replacing traditional components with cutting-edge electric systems. Here’s what the transformation looks like:

Replaced Components:

- Diesel engine

- Transmission

- Torque converter

- Differential

- Radiator

- Final drives

- Fuel tank

Upgraded to:

- High-capacity batteries

- Electric traction motors

- Advanced cooling systems

This transformation reduces the truck’s weight, allowing for an increased payload. By eliminating heavy components and integrating lighter, more efficient systems, the truck’s empty weight decreases significantly. This enables a payload increase of approximately 9 tonnes, maintaining a maximum gross vehicle weight (GVW) of 386 tonnes. The result? Enhanced productivity and optimized material transport per trip.

Technical Performance

NewSteel’s electric trucks incorporate advanced technologies to maximize performance and efficiency:

- Maintenance Management System (CMMS): IoT-enabled real-time monitoring supports predictive maintenance, reducing downtime and enhancing operational efficiency.

- Artificial Intelligence (AI): AI analyzes operational data to optimize performance, ensuring all components function at peak capacity.

Key reliability metrics include:

- Mean Time Between Failures (MTBF): 120 hours, showcasing high operational reliability.

- Mean Time to Repair (MTTR): Just 2 hours, ensuring quick turnaround times.

- Mean Time Between Stops (MTBS): 160 hours, supporting extended, uninterrupted operations.

The comprehensive maintenance strategy includes regular inspections, preventive care, continuous innovation, and remote management to ensure trucks operate at peak performance.

Electric vs. Diesel: A Clear Advantage

Compared to traditional diesel technology, NewSteel’s electric trucks deliver significant benefits:

- Maintenance Savings: Over a 5-year period, operating a fleet of 10 electric trucks can save approximately USD 16.4 million due to reduced maintenance requirements.

- Energy Cost Savings: Lower energy costs translate to USD 15.1 million in savings over 5 years, leveraging Australia’s favorable electricity rates compared to diesel fuel.

- Rapid ROI: Initial investment can be recouped in as little as 6 months, as detailed in our guide to investment recovery.

These advantages position electric trucks as a smarter, more sustainable choice for Australian mining companies.

Technological and Operational Benefits

Electric truck conversion offers a range of cutting-edge advantages:

- Energy Efficiency: Reduced energy consumption and carbon emissions contribute to cleaner, greener mining operations.

- Noise Reduction: Quieter operations create a safer, more comfortable work environment for miners.

- Payload Increase: Reduced truck weight enables higher payloads, boosting overall productivity.

- Smart Systems: Advanced control systems improve fleet management, ensuring swift responses to operational demands.

Corporate Benefits for Australian Mining Companies

Adopting electric truck technology benefits not just operations but also corporate reputation:

- Sustainability Leadership: Demonstrate a commitment to environmental responsibility, enhancing brand image and stakeholder trust.

- Government Incentives: Access Australian green energy incentives and financing options to lower costs and improve financial feasibility.

- Regulatory Compliance: Stay ahead of tightening global environmental regulations by adopting clean technologies today.

Why NewSteel is the Right Choice

For Australian mining companies aiming to lead in efficiency and sustainability, NewSteel’s electric truck conversion is an unmatched opportunity. This process not only reduces environmental impact but also future-proofs operations for stricter environmental policies. Adopting this cutting-edge technology today offers a significant competitive edge.

To learn more about transforming your fleet with NewSteel, connect with us on WhatsApp, LinkedIn, or Instagram. Lead the way in modern mining!