Rapid charging is essential for maximizing the operational efficiency of NewSteel’s electric trucks in mining. With just a 1-hour charge, these trucks can operate for 7 continuous hours, enabling more efficient and uninterrupted operations. Mining companies looking to boost productivity without compromising on sustainability are increasingly choosing electric trucks for their operational needs.

Why Is Rapid Charging Essential in Mining?

In mining operations, every minute counts. The ability to recharge trucks in 1 hour and achieve 7 hours of uninterrupted operation significantly reduces downtime and optimizes overall costs. Traditional diesel trucks require multiple fuel stops, leading to frequent operational pauses.

NewSteel’s smart loading systems provide a crucial advantage. They allow trucks to recharge during scheduled breaks or shift changes, ensuring minimal downtime. This smart scheduling helps mining companies achieve higher productivity and maintain uninterrupted workflows.

High Autonomy: Maximizing Operational Output

NewSteel’s electric trucks are not only about rapid charging—they also offer high autonomy, allowing for continuous operation over extended periods. Each charge cycle guarantees 7 hours of performance, eliminating the need for multiple interruptions throughout the shift.

- Optimized for Harsh Environments: Designed to withstand extreme weather and challenging terrains, NewSteel trucks operate reliably in both open-pit and underground mining conditions.

- Continuous Workflow: With fewer interruptions, trucks can maximize their haul cycles, improving both productivity and output during shifts.

How Rapid Charging and High Autonomy Benefit Mining Operations

Imagine a 24/7 mining operation where efficiency is critical. A NewSteel electric truck requires only 1 hour of charging to deliver 7 hours of continuous work. Compared to diesel trucks that require multiple refueling stops, electric trucks maximize uptime and reduce idle periods.

The rapid charging system is particularly advantageous for high-demand mines looking to eliminate unnecessary pauses and improve their operational efficiency.

Economic Benefits: More Savings, Faster ROI

The adoption of NewSteel’s electric trucks translates into substantial cost savings:

- 80% Savings on Fuel Costs: By eliminating fossil fuel dependence, companies significantly reduce operational expenses.

- 90% Reduction in Maintenance Costs: Electric trucks have fewer moving parts, reducing breakdowns and maintenance intervals.

These savings allow companies to achieve a return on investment in as little as 6 months, making the switch to electric trucks both practical and profitable.

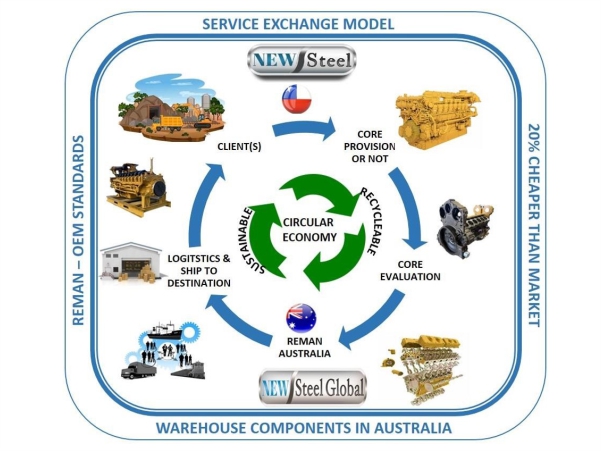

Sustainability: A Greener Future for Mining

NewSteel’s electric trucks also align with modern sustainability goals. By eliminating greenhouse gas emissions, mining companies reduce their carbon footprint and comply with strict environmental regulations.

This approach not only enhances a company’s reputation but also contributes to a more sustainable future for the mining industry. To learn more about how NewSteel trucks support efficient and sustainable mining, explore our additional resources.

Uninterrupted and Sustainable Operations with NewSteel

Rapid charging for electric trucks is a game-changing solution for mining companies looking to improve efficiency, reduce costs, and operate more sustainably. With 7 hours of autonomy and quick 1-hour recharges, NewSteel’s trucks enable uninterrupted, sustainable, and cost-effective operations.

If you’d like to learn more about how NewSteel’s technology can optimize your fleet, contact us here or follow our updates on LinkedIn and Instagram.