At NewSteel, we’re committed to the quality and reliability of our remanufactured engines. One key test we perform to ensure optimal performance is the DinoTest. This process involves three main stages: preparation, testing, and reviewing results. Here’s a closer look at each stage using the example of the 797F engine, which we recently tested successfully.

To learn more about our REMAN products, visit NewSteel REMAN Products.

1. Preparing for the DinoTest

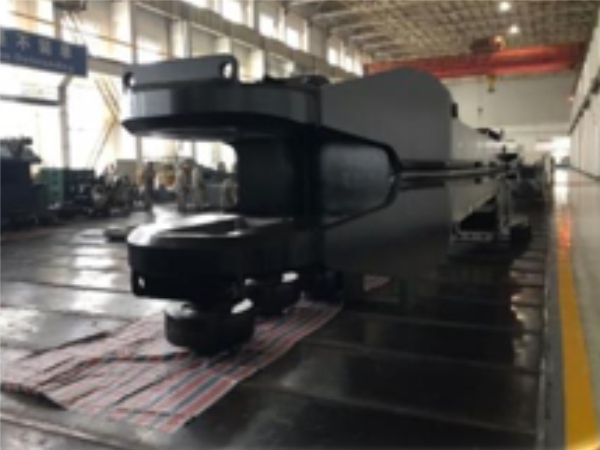

Getting the engine ready is a critical step to ensure the test’s validity. During this phase, we carry out the following:

- Visual and Mechanical Inspection: Our team conducts a thorough inspection to identify and fix any visible or mechanical issues.

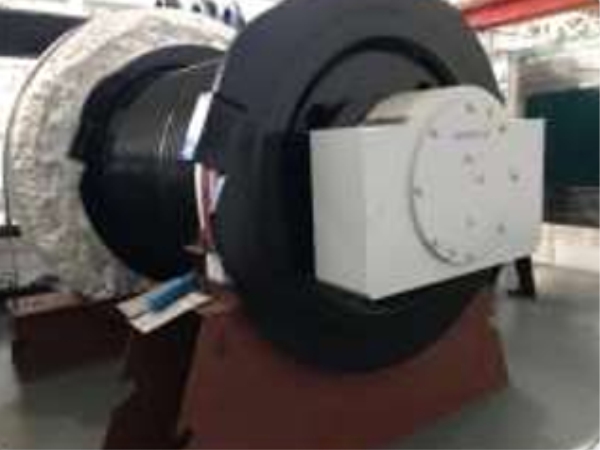

- Mounting and Setup: Technicians mount the engine on the test bench, ensuring all systems are properly connected and calibrated.

- Pre-Test Checks: We perform preliminary tests to ensure all sensors and measuring equipment work correctly.

2. Conducting the DinoTest

Once the engine is ready, we proceed with the DinoTest. This stage is crucial to evaluate the engine’s performance under controlled conditions. The steps include:

- Starting and Warming Up: The team starts the engine and allows it to run until it reaches its optimal operating temperature.

- Power and Performance Testing: Specific tests measure the engine’s power. For the 797F engine, it reached over 4000HP, demonstrating its capability and reliability.

- Data Recording: We collect detailed data on the engine’s performance, including its power, efficiency, and any signs of wear or issues.

3. Reviewing the Results

The final stage of the DinoTest involves a detailed review of the results. This ensures the engine is ready for delivery and real-world operation. Key activities include:

- Data Analysis: Our engineers analyse the collected data to verify the engine meets all technical specifications and quality standards.

- Results Report: We prepare a comprehensive report detailing the engine’s performance and any maintenance recommendations.

- Certification and Delivery: Once the engine passes all tests, we certify its quality and prepare it for shipment to the client, ensuring it arrives in perfect condition.

The DinoTest is an integral part of our commitment to quality and reliability at NewSteel. Through this process, we ensure that each remanufactured engine not only meets but exceeds our customers’ expectations. From initial preparation to final review, each stage is designed to guarantee maximum performance and durability of our products.

Interested in learning more about our processes and products? Contact us today and discover how our remanufactured engines can optimise your mining operation. Follow us on Instagram and LinkedIn to stay updated on our latest innovations and news. For direct inquiries, feel free to message us on WhatsApp. We guarantee quality and reliability in each of our products!