Since the early days of mining, trays have been essential for the transport and handling of materials. Over the years, the evolution of mining trays has been significant. Today, NewSteel is at the forefront of this evolution, with innovations that are transforming the mining industry.

The History of Mining Trays

The first mining trays were simple and rudimentary structures made of wood and later metal, designed to facilitate the handling of ores and other heavy materials. Initially, these trays were manually operated and had limited capacity. With the advent of the industrial revolution, the demand for efficiency and capacity increased, leading to significant improvements in the design and functionality of mining trays.

During the 20th century, mining trays underwent important technological advancements. The introduction of new materials and manufacturing techniques allowed for the creation of more durable trays with greater load capacity. Innovations in mechanical design also made partial automation possible, enhancing safety and efficiency in mining operations. The evolution of mining trays has been marked by these advancements.

Key Innovations by NewSteel

NewSteel has transformed mining trays with a focus on durability, efficiency, and sustainability. The Bolted Truck Body (BTB) trays by NewSteel stand out for their modular design, which allows for quicker and easier assembly and maintenance. This feature is especially valuable in modern mining, where downtime can be costly.

Additionally, NewSteel’s BTB trays are compatible with a wide range of OEM trucks, making them a versatile and adaptable option for various mining operations. The anti-wear and modular technology used in these trays ensures a prolonged lifespan, reducing the need for frequent replacements and thus contributing to the sustainability of mining operations.

Industry Impact

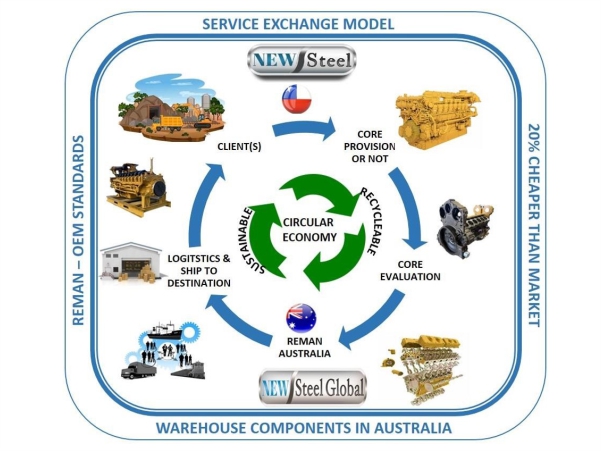

NewSteel trays not only improve operational efficiency but also help reduce costs and minimize environmental impact. By using recyclable materials and sustainable manufacturing processes, NewSteel supports the circular economy, an approach that seeks to reduce waste and maximize resource use.

These innovations are setting new standards in modern mining. NewSteel trays enable significant logistics optimization, enhancing load capacity and reducing fuel consumption. Additionally, the implementation of advanced technologies like IoT and Big Data in NewSteel trays is taking operational efficiency to new levels. The evolution of mining trays continues, driven by these innovations.

The evolution of mining trays reflects the advancements in technology and the growing demands of the mining industry. NewSteel continues to lead this evolution, offering solutions that combine tradition and innovation for a more efficient and sustainable future. For more information and updates on our innovations, follow us on Instagram, connect with us on LinkedIn, or contact us directly via WhatsApp.