Electric truck conversion is becoming an essential part of modern mining. It helps companies improve sustainability, enhance operational efficiency, and reduce costs. Below, we outline four key reasons why this transformation is critical and how it can benefit your operations.

1. Sustainability: A Necessary Change

The need to comply with stricter environmental regulations is driving the transition to electric trucks. Governments and regulatory bodies are pressuring industries to lower their carbon footprint, and electric trucks are central to this effort.

- Zero Emissions: Electric trucks eliminate greenhouse gas emissions entirely. This helps companies meet regulatory standards and improves their reputation as sustainability leaders.

- Reduced Noise Pollution: These trucks are much quieter than traditional models. This not only enhances working conditions but also minimizes noise pollution in and around mining sites. For example, electric trucks enable quieter operations, a major challenge for many mines read more about this innovation.

2. Greater Efficiency and Lower Operating Costs

Electric truck conversion offers significant cost savings while improving operational efficiency. These advantages are reshaping the economics of mining.

- Fuel Savings: Replacing diesel with electricity can save companies up to 80 percent on fuel costs. This reduction lowers expenses and also stabilizes budgets by removing the uncertainty of fuel price fluctuations.

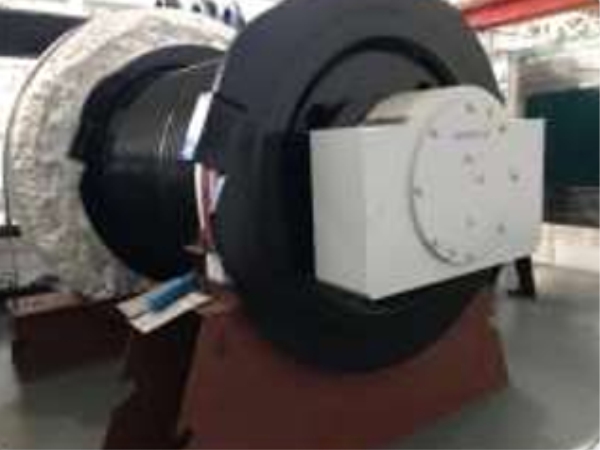

- Reduced Maintenance Costs: Electric trucks require fewer repairs due to their simpler design. Companies report maintenance cost reductions of up to 90 percent. This change is dramatically improving fleet reliability and minimizing downtime explore these benefits further.

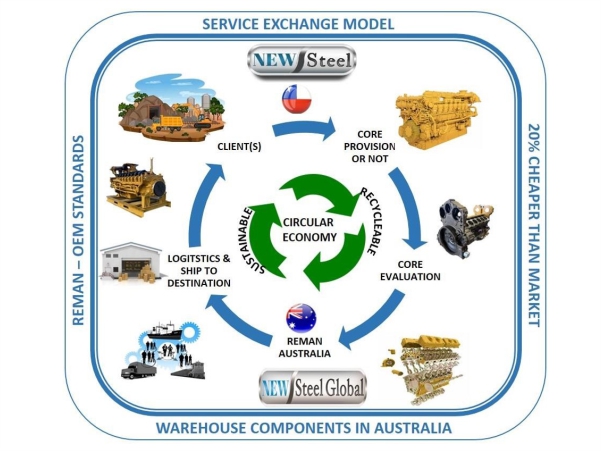

3. Adapting to the Circular Economy

Mining companies are increasingly adopting the circular economy model. This approach focuses on minimizing waste and reusing resources, and electric truck conversion supports these goals.

- Truck Reuse: Instead of replacing entire fleets, companies can retrofit existing combustion trucks. This process extends the life of their vehicles and reduces the need for new manufacturing.

- Repurposing Components: Many parts from old trucks can be reused during conversion. This reduces waste and aligns operations with sustainability goals. These practices are crucial for creating more resource-efficient mining operations as outlined in our guide.

4. Future Readiness: Reduced Operational Risks

Electric truck conversion prepares mining companies for the future. It positions them to overcome rising challenges and adapt to new industry standards.

- Less Energy Price Volatility: Electricity is a more stable energy source than diesel. By adopting it, companies can better manage costs and plan for long-term operations.

- Advanced Charging Technology: NewSteel’s electric trucks charge in just one hour. This fast-charging feature provides up to seven hours of continuous operation, ensuring minimal interruptions to productivity.

Bonus: NewSteel, the Leading Ally in Electric Truck Conversion

With extensive experience in the mining sector, NewSteel has become a trusted leader in electric solutions. Our advanced technology helps companies of all sizes transition to more efficient and sustainable operations. By focusing on innovation, we ensure that every fleet is equipped to meet future challenges.

We specialize in optimizing mining operations for both productivity and sustainability. With NewSteel, the transition to electric truck conversion is smooth, cost-effective, and designed for success.

Electric Truck Conversion is the Future of Mining

Electric truck conversion is more than a trend—it is essential for companies that want to stay competitive. By adopting this technology, mining businesses can improve efficiency, sustainability, and profitability. With NewSteel, upgrading your fleet has never been easier or more rewarding.

Are you ready to make the change? Contact us here to begin the electric transformation of your fleet. Don’t forget to follow us on Instagram for the latest updates.