The World most innovative Bowl Truck Body

Elements for the Bolted Truck Body (BTB) Dump Body are primarily fixed with bolts, making its repair on the truck easier and reducing the repair time. There's no need to remove welds, just extract the bolts from the affected area. Being sectional, it can be moved in parts and assembled on-site, avoiding transportation issues due to its size, especially in mines accessed through tunnels.

Are you interested in learning more? Contact us to schedule a presentation.

Easy to transport, does not require permits.

Assembly time in mine: 2 Days.

Low maintenance cost.

Bolted Together

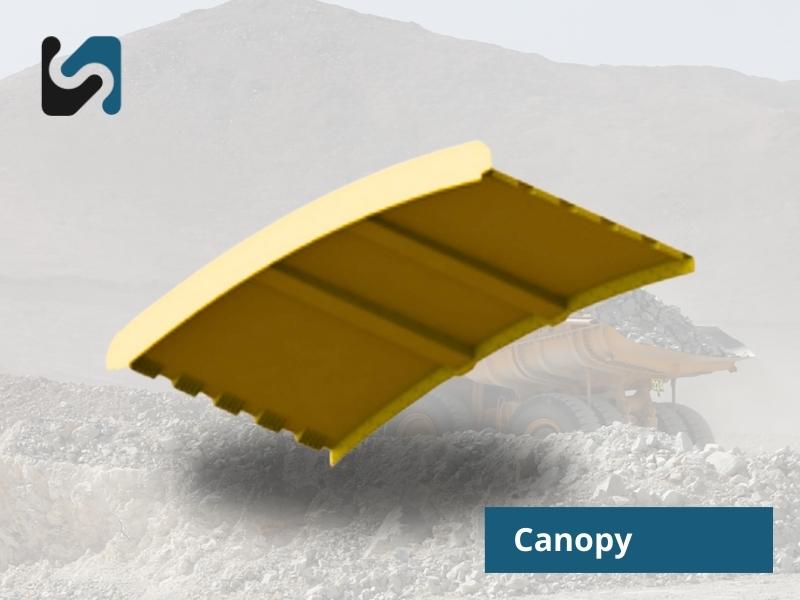

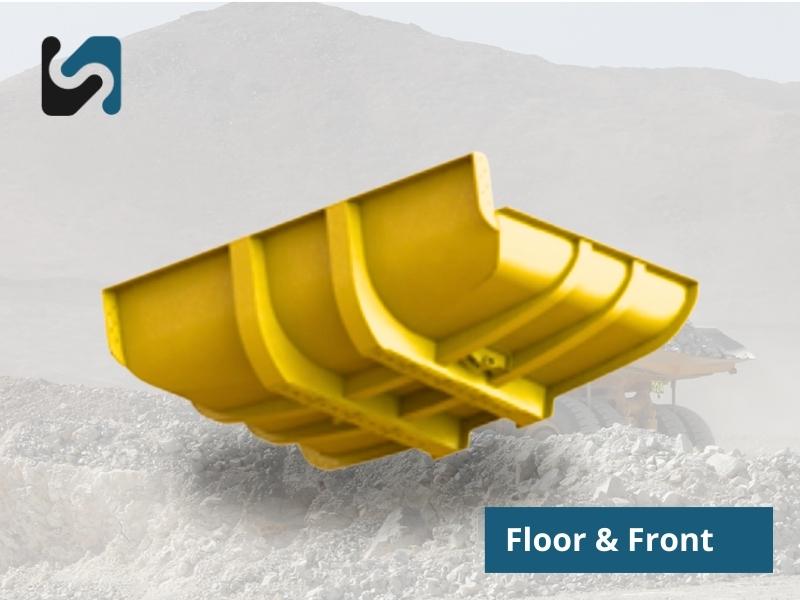

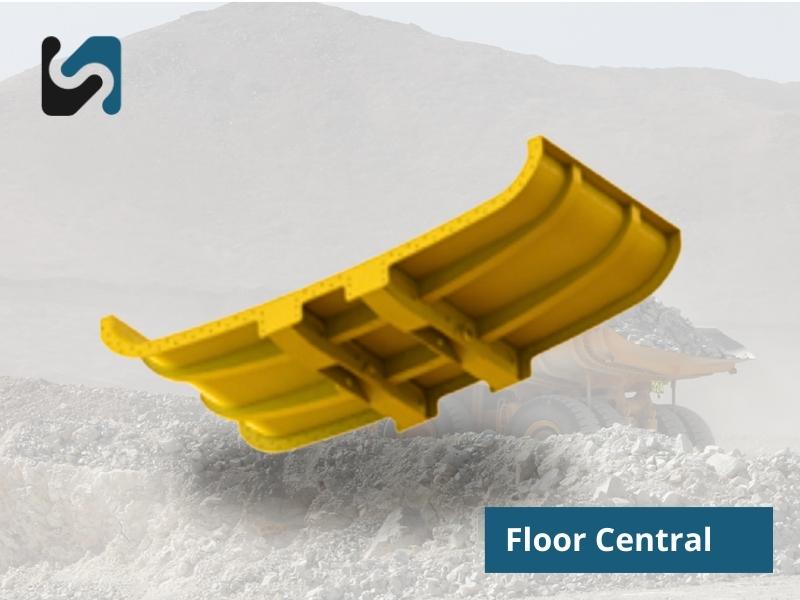

Its 7-part mechanism can be easily assembled on-site in only two days without welding and can be easily disassembled and repaired onsite.

7 Interchangeable Pieces bolted together

The Bowl (Bolted Truck Body) design challenges the status quo in these economic times by providing significant savings to the mining haulage industry.

The BTB's unique "modular" structure can be easily transported in parts in containers. This means, no more costly permits! Making it more cost-effective.

Easy to maintain in-house without having to move trays off-site to workshops, repair reducing risk, and extremely safe to work on, particularly on repairs. Above all, it can provide you with significant gains in payload reducing your overall cost.

What are the advantages of acquiring the Bowl (Bolted Truck Body) Hopper?

The mechanical Bowl Hopper is designed to transport large volumes of ore and waste, suitable for high-tonnage trucks. It is characterized by a variety of beams in its structure, with sectional floor plates, front wall, side walls, over-sides, visor, stone boot holder, and load deflectors, all primarily bolted together. Our goal is to be global leaders in mining product services.

90% Increase in asset availability at a low personnel maintenance cost.

Low transportation cost: Move Hoppers in 20 and 40-foot containers.

90% Reduction in maintenance risk exposure due to design.

Interchangeable parts - the only Bowl Hopper in the world with low repair and part exchange costs.

Easy to transport and assemble anywhere, Circular Economy.

No need for wide load transport, no escorts or special permits required.

Are you interested in learning more? Contact us to schedule a presentation.

We are a World-Class Company

We achieve this through a focus on cost reduction, service capability, and reliability, providing support and value to our clients in design, engineering, manufacturing, procurement, and technical services for the mining industry.

Best solution for your needs in the mining industry

That is why at Newsteel we are committed to our clients and their projects. Looking for personalized attention and building the best long-term relationships.

Are you interested in learning more? Contact us to schedule a presentation.